Line feeding equipment

Key words:

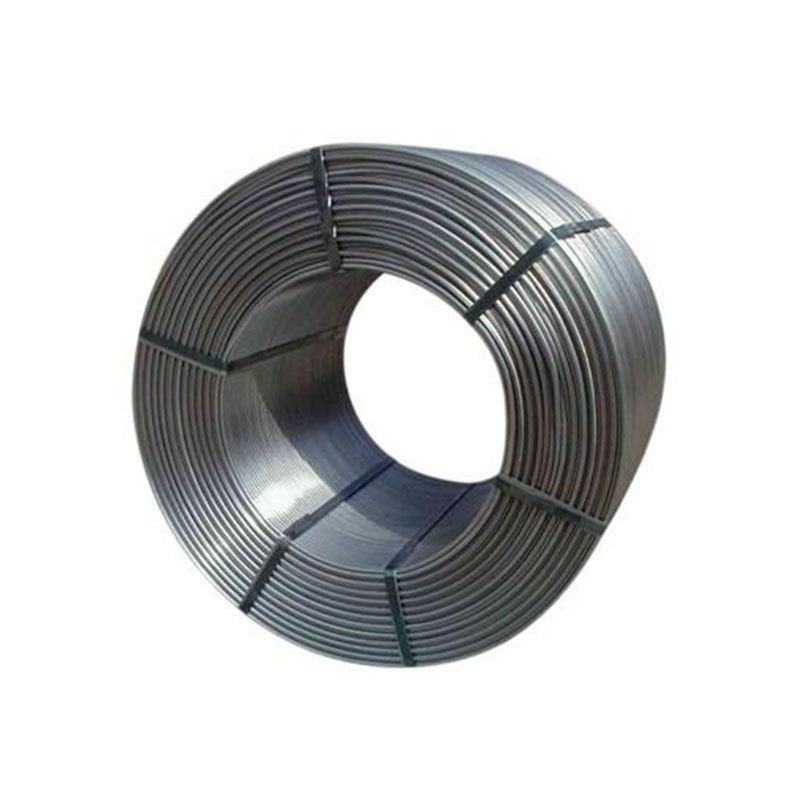

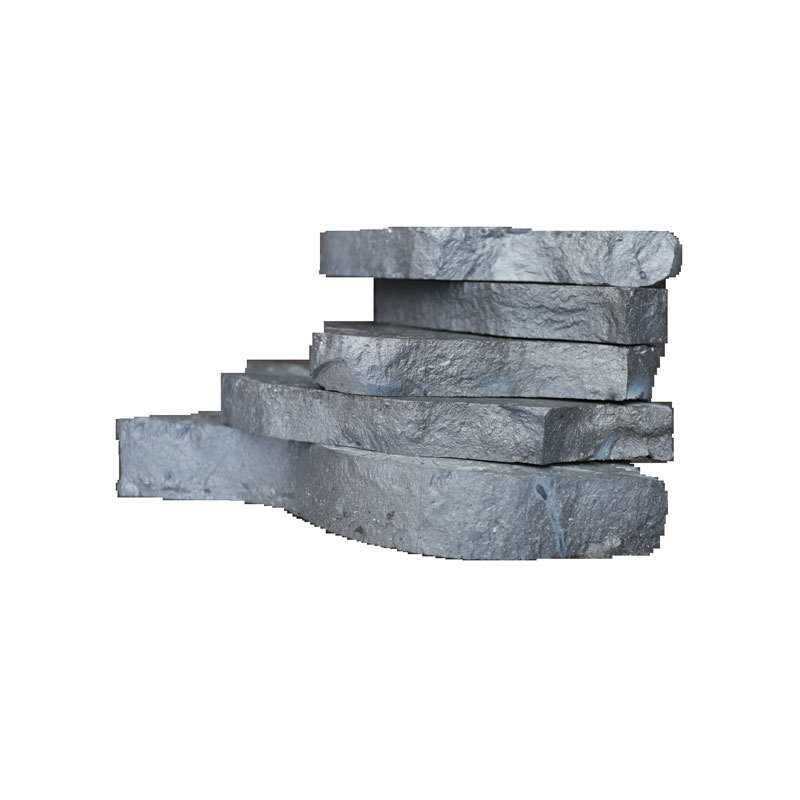

Cored wire, spheroidizing agent, inoculant

Classification:

Details

Product Introduction

The wire feeding process is a new process of iron liquid spheroidization and inoculation treatment, which is to accurately feed the spheroidized core wire and inoculation core wire into the iron liquid vertically under automatic and intelligent conditions. The controlled feeding speed can realize the melting of the core wire at the specific position at the bottom of the iron liquid, release the contained elements, and increase the contact time between the elements and the iron liquid, so as to play the role of spheroidization and inoculation elements more effectively. At the same time, through fixed-point spheroidization, centralized dust collection can be realized, the environment can be improved, and the labor intensity of workers can be reduced.

Conditions of use

1, suitable for cast steel, cast iron deoxidation, modification, spheroidization, inoculation and other feeding line treatment;

2. The height-to-diameter ratio of the treatment liquid in the treatment package is greater than 1.2:1;

3. Power requirements for wire feeder: AC380V 50Hz + 5% three-phase five-wire system;

4. Compressed air requirements: dry air, pressure 0.4-0.6Mpa, flow 0.3-0.5 m3/min.

Conditions of use

Display function: display the preset feeding length, speed, withdrawal length and feeding length of the wire feeder, as well as the feeding time.

Memory function: it can record the running parameters of the wire feeding machine and remember the running parameters of the previous job.

Preset function: it can preset the process parameters such as running speed, joining length and exit length of multi-species cored wire, which is convenient to call quickly during production.

Data export function: historical data of feeding line is stored on U disk in EXCEL format, which is convenient for data backup, query and transmission.

Speed control function: According to production needs, the feed line speed can be selected and adjusted through the touch screen.

Automatic parking function: when the amount of core wire reaches the preset parameters, when the wire feeding machine slips or breaks in the working process, and when the frequency converter of the wire feeding machine fails, the wire feeding machine will stop automatically.

Simplified operation function: in the production process, the same type of cored wire, when dealing with the same molten iron, does not need to set the operation parameters of the wire feeder every time, only needs to select a preset variety, and press "one key start" every time, the wire feeder can run.

Preventing false counting function: "slip" or "disconnection" occurs during the working process of the wire feeding machine, and the counting wheel does not count, automatically stops and alarms to avoid the phenomenon of "counting false numbers.

Automatic line withdrawal function: the line feeder will stop automatically after adding the preset length. After a delay of 3 seconds, it can withdraw the line according to the predetermined line withdrawal length. When the line withdrawal length is reached, it will stop automatically.

A variety of automatic protection functions: when the wire feeder has overload, overcurrent, overheating, overvoltage, undervoltage and other faults, it can automatically stop and give a warning.

Application Scenarios

Wind power generation

High-speed railway

Aerospace

Nuclear power field

Related Products

Product Inquiry