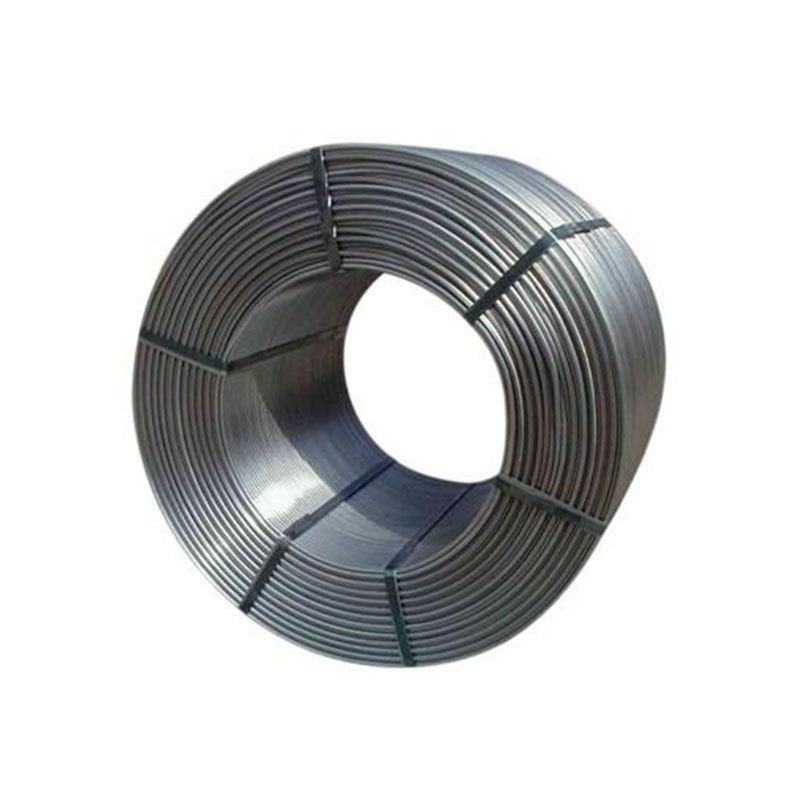

Cored wire

Key words:

Cored wire, spheroidizing agent, inoculant

Classification:

Details

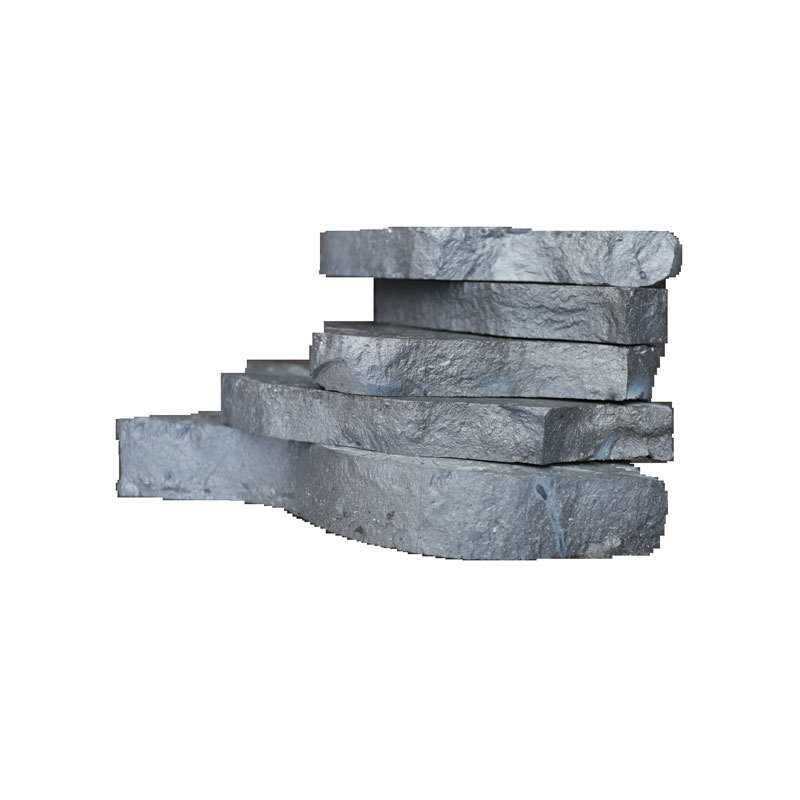

Cored wire technology generally refers to cored wire manufacturing technology and cored wire application technology. It firstly breaks various additives (such as spheroidizing agent, inoculant, creeping agent, desulfurizer, deoxidizer and modifier) into a certain particle size, wraps the core wire with steel belt, and then adds the core wire into the metal liquid to be treated by means of a wire feeding machine. With the melting of the steel skin, the additives are brought into the metal liquid and react accordingly, the external process can realize computer control and automatic feeding.

The comprehensive application of gas-protected alloy remelting, closed rapid solidification molding, nitrogen-protected granulation and other technologies has improved the purity, density and composition uniformity of the core alloy, reduced the magnesium oxide content and ensured the stability of product quality. The anti-false package software control system in the thread making process automatically controls the feeding amount and thread making speed according to the parameters such as thread pressure and material level, the uniformity and consistency of the unit core weight of the core wire are guaranteed.

Production process

Medium frequency furnace melting, metal solidification, gas protection granulation, process online control.

Product Features

MgO/Mg<5.0; high density, small segregation of core composition, core weight error ≦ 5 g/m, etc.

Product category

Φ10mm and Φ13mm two specifications, remelting, layering and mixing three kinds of process production of each brand of spheroidizing line, spheroidizing process inoculation line, with the flow inoculation line, creeping line, passivation line, cast steel deoxidation line and other series of products, according to the production conditions.

Application Scenarios

Wind power generation

High-speed railway

Aerospace

Nuclear power field

Related Products

Product Inquiry