News & Events

Application of heating and heat-insulating riser sleeve in pouring of vacuum induction melting furnace

Release time:

2024-01-30

Thermal insulation riser sleeve is a thermal insulation product used in casting castings in the metallurgical industry. In the past, cement products with lightweight thermal insulation materials such as expanded perlite and ceramsite were used as aggregates, and fiber composite products were also used abroad. The floating bead has superior high temperature resistance, heat insulation and heat preservation performance, and has no effect on the composition of the steel grade. Therefore, the floating bead type heat preservation riser is selected. The floating bead insulation riser is a kind of insulation product made by mixing, molding, drying and other processes with pure floating beads as the aggregate and water glass as the gel material.

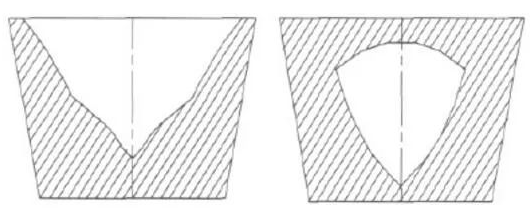

Vacuum induction furnace smelting is a smelting method of heating, melting, refining, alloying and pouring under negative pressure. Since all metallurgical processes are carried out in isolation from the atmosphere, atmospheric pollution of molten steel is avoided. Molten steel is refined under vacuum, which can significantly improve its purity and accurately control the chemical composition of the steel. Due to the limitation of the size of the vacuum chamber, the general use of vacuum furnace smelting is basically a blank or master alloy, followed by such as electroslag remelting, forging, rolling and other hot processing processes. The vacuum induction melting furnace of our unit mainly produces steel ingots, and then rolls and pulls them to make welding wires of different specifications. This requires the ingot to have a better pouring quality, the internal is not allowed to have loose, inclusion, shrinkage and so on. In the atmospheric state, the upper surface of the steel ingot may be finally solidified by feeding by adding a coating agent or the like, thereby forming the steel ingot having the cross section shown in FIG. 1. However, in the vacuum state, due to the lack of feeding means, the steel liquid will be solidified from each surface at the same time, often in the heart of different degrees of shrinkage, as shown in Figure 2, greatly affecting the yield.

Thermal insulation riser sleeve is a thermal insulation product used in casting castings in the metallurgical industry. In the past, cement products with lightweight thermal insulation materials such as expanded perlite and ceramsite were used as aggregates, and fiber composite products were also used abroad. The floating bead has superior high temperature resistance, heat insulation and heat preservation performance, and has no effect on the composition of the steel grade. Therefore, the floating bead type heat preservation riser is selected. The floating bead insulation riser is a kind of insulation product made by mixing, molding, drying and other processes with pure floating beads as the aggregate and water glass as the gel material.

Recommended News